All About Fasteners Episode 10: Two ways to install anchors in concrete or masonry – mechanical and chemical bonds

ITW offers two superb chemically-bonded anchoring systems: RED HEAD C6+, an epoxy-based product; and RED HEAD A7+, a “hybrid” product.

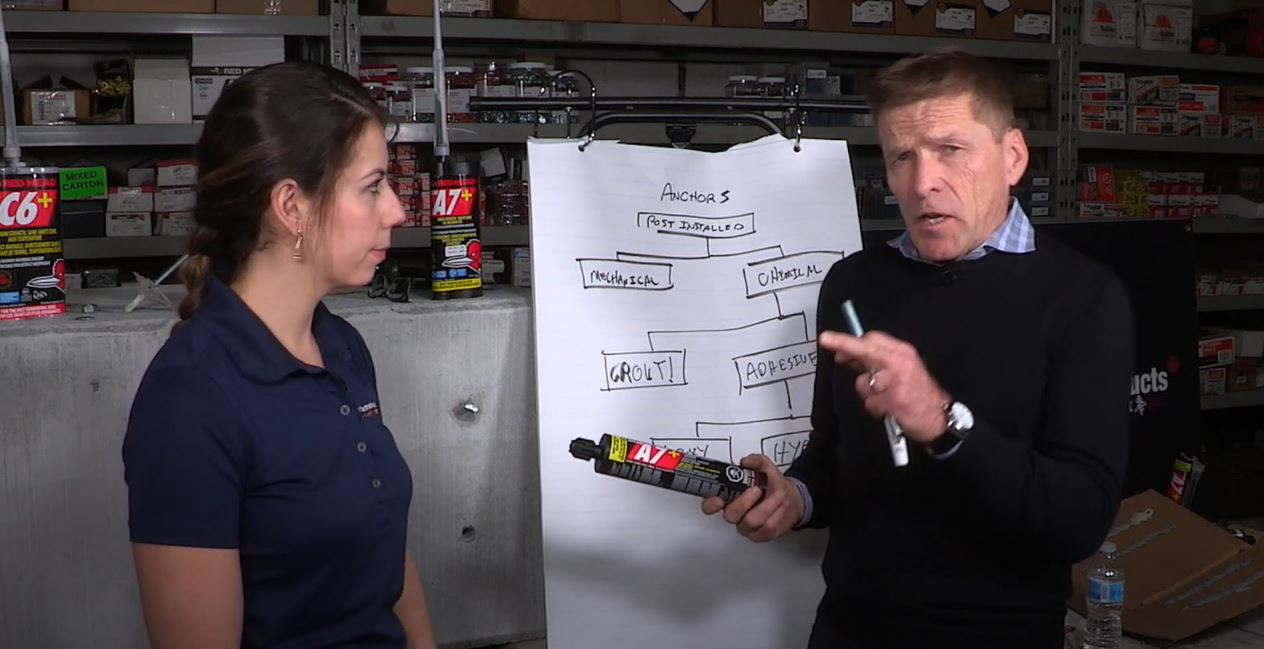

In this short 4 minute video, Rob Koci is once again joined by Andrea Galindo, Technical Services Specialist for ITW Construction Products Canada.

Rob and Andrea discuss two methods to install anchors (or bolts) in masonry and concrete to achieve maximum strength.

Mechanical anchors are familiar to most of us. ITW’s TAPCON fasteners are great products. There are two types: screws and wedge anchors. The latter expand as you tighten them down, enlarging the special end of the fastener to press into a tight fit with the substrate.

Chemically-bonded anchors are the focus of this video. There are two broad types of chemical bonds for anchors: Grout (which is a cement-based material we are all familiar with) and Adhesives. Adhesives can be broken down into two types: Epoxy and Hybrids.

Epoxy-based adhesives contain resin-to-hardener ratios of 3:1, 2:1 and 1:1. ITW distributes a great product called Red Head C6+High-Strength Epoxy. It’s great for higher loads under extreme conditions. Rob and Andrea demonstrate this product.

Hybrid adhesives have a 10:1 resin-to-hardener ratio. ITW has another great product in this line, called Read Head A7+ Quick-Cure Adhesive. A7+ is a highly-versatile product that all renovation contractors and homebuilders should become familiar with, if they are not already. A7+ comes in a 10 oz. and a 28 oz. cartridge. The 10 oz. version will fit in a regular caulking gun. The 28 oz. version requires a special, larger caulking gun.

When using such adhesives with resins and hardeners, when you first apply the product from a new cartridge, the product will at first come out white or lighter-coloured. You want to make sure you squeeze it a bit more until a uniform grey colour appears. That way, you know the resin and the hardener are coming out mixed in the proper proportions.

This video was shot at ITW’s test facility in Markham, Ontario.